Welcome to CAD Fusion

Engineering Solutions Pvt. Ltd.

Founded by *Ms. Shalini Das, CAD Fusion Engineering Solutions Pvt. Ltd. has grown into one of the most reliable names in the engineering services sector in Kolkata. With **10+ years of experience* and a portfolio of *500+ successful projects*, we are driven by a passion for product innovation and functional design. Our team combines engineering excellence with state-of-the-art technology to deliver custom solutions that meet our clients' needs—on time and within budget. From idea to prototype to final production, we are your complete product development partner.

The art of living in a work

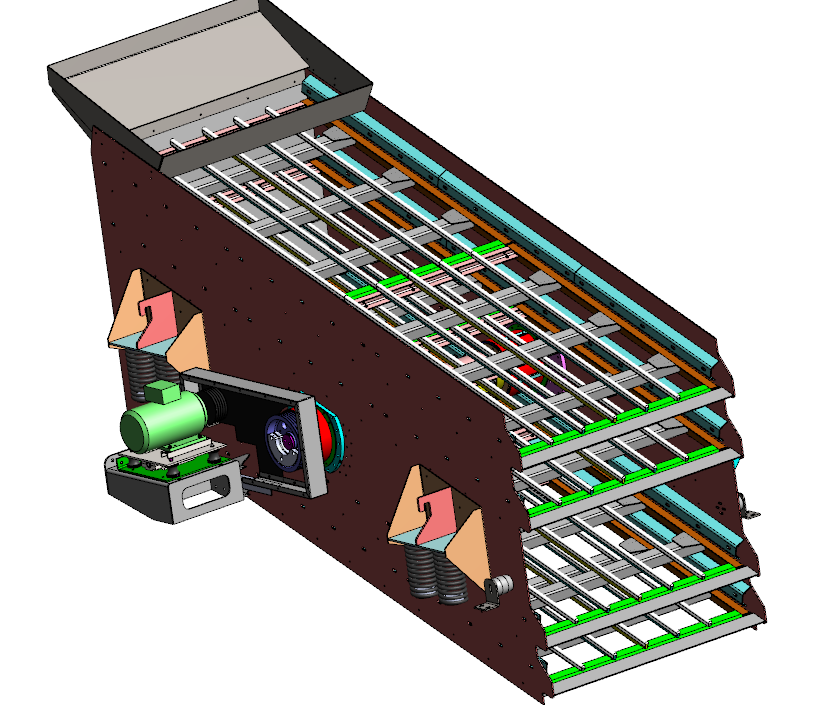

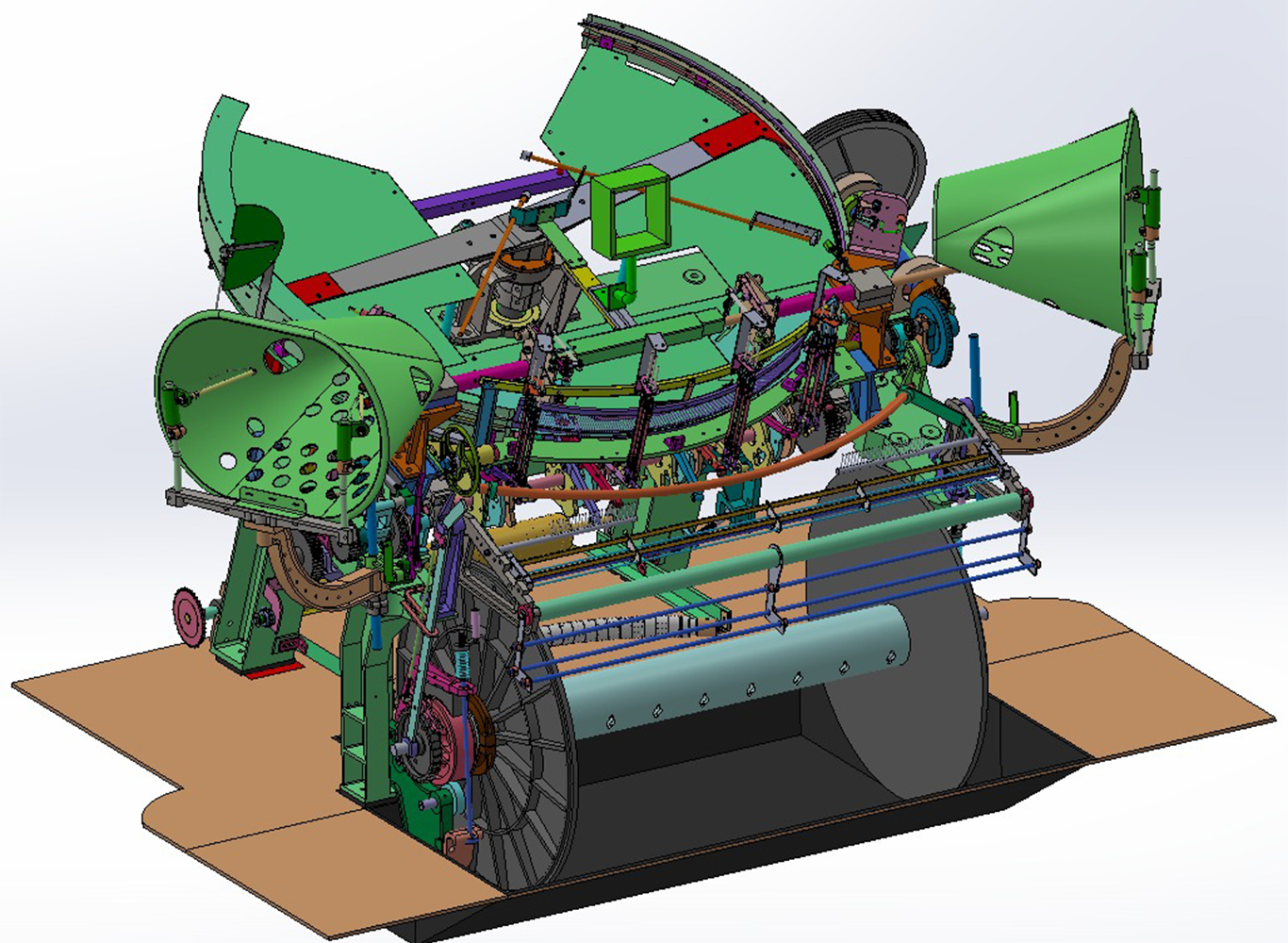

We take pride in every project we’ve completed. From industrial tools to consumer products, our gallery showcases our commitment to quality, innovation, and detail.

Established by Shalini Das, CAD Fusion Engineering Solutions Pvt. Ltd. is a leading engineering solutions provider based in Kolkata, with over 10 years of industry expertise. With a proven track record of delivering over 500+ successful projects, we specialize in providing comprehensive product design, development, and analysis services to clients across Howrah, Kolkata, and beyond.

Our mission at CAD Fusion Engineering Solutions Pvt. Ltd. is to empower innovation through precision engineering. We are committed to delivering cutting-edge design, prototyping, and manufacturing solutions that help our clients turn ideas into reality. By combining advanced technology with deep industry expertise, we aim to be a trusted partner in product development, reverse engineering, and digital transformation—driving value, quality, and excellence in every project we undertake.

10+

Years of experience

500+

Successful projects

15

Best designers

5

Worldwide branches

With a strong focus on quality, innovation, and precision, we cater to a diverse portfolio of corporate and industrial clients, ensuring high performance and reliability in every solution we deliver.

Based in Kolkata, proudly serving clients across Howrah and the greater West Bengal region.

What services does CAD Fusion Engineering Solutions offer?

We specialize in 3D printing, 3D scanning, reverse engineering, CAD drawing generation, mold/die design, prototype development, aesthetic design, and static/dynamic analysis with report generation.

Do you provide customized product design services?

Yes, we offer end-to-end customized product design and development solutions tailored to your industry needs and specific requirements.

What industries do you serve?

We work with clients across various sectors including automotive, aerospace, consumer electronics, manufacturing, and medical devices.

Can I get a prototype before full-scale production?

Absolutely. We provide detailed prototype design and 3D printing services to validate your concept before moving to mass production.

Do you offer reverse engineering of old or broken parts?

Yes, we use advanced 3D scanning and CAD tools to accurately reverse engineer damaged or legacy parts and recreate detailed models.

How long does a typical project take?

Project timelines vary based on complexity, but we always aim to deliver high-quality results within agreed deadlines, often within a few days to weeks.

Are you available outside Kolkata?

Yes, while we are based in Kolkata and serve Howrah as a primary target area, we also work with clients from across India.

How can I get a quote or start a project?

You can contact us via phone at +91 9123072381, WhatsApp us, or email us at cadfes2025@gmail.com. Share your requirements, and our team will get back to you with a detailed proposal.

Let's create

a project for

you

Our team designed and 3D printed a functional prototype for a handheld medical diagnostic device. The project involved aesthetic modeling, ergonomic analysis, and real-time design iterations—delivering a production-ready model within tight deadlines.